Understanding Power Quality Issues in Industrial Setups

What Is Power Quality and Why Does It Matter?

Definition of Power Quality

When it comes to industrial electrical systems, few factors are as important as power quality. But what exactly is power quality? This is defined as the consistency, stability and reliability of input power to equipment in such a way that it operates well within the norms of acceptable voltage and frequency.

The Cost of Poor Power Quality in Industrial Facilities

There is a major cost to pay for poor power quality, especially in the industrial sector. First and foremost, it directly translates to a loss in power. This is vital from a monetary perspective as poor quality will lead to more energy consumption, directly driving up the cost.

However, the more pressing problem is the potential damage it can cause to industrial equipment. Due to poor power quality, the system can be exposed to overheating, which can erode the longevity and performance of the particular equipment. This leads to more downtime in the long run as the equipment is more likely to break down.

This is why having stable power is so vital for modern industry.

Role of Stable Power in Modern Industrial Equipment

There are numerous benefits of having stable power. Primarily, it protects the equipment from damage that may arise from power quality issues. Next, it also improves productivity by reducing overall downtime. Lastly, it also optimizes the performance of the equipment.

Common Power Quality Issues in Industrial Environments

With a clear understanding of the effects of power quality, here is a look at a few major power quality challenges/issues faced in industrial environments:

Voltage Sags and Swells

As the name suggests, sags and swells occur when the voltage either drops to 90 percent or below nominal levels or increases beyond capacity, respectively. Some common side effects of voltage sags or swells include damage to sensitive equipment.

Transients and Surges

Transients are similar to a voltage surge, but there is one major difference. Instead of a consistent increase in voltage, this surge lasts for microseconds at most. Lightning strikes are one of the most common causes of this phenomenon. Consequences include damage to equipment as well as insulation.

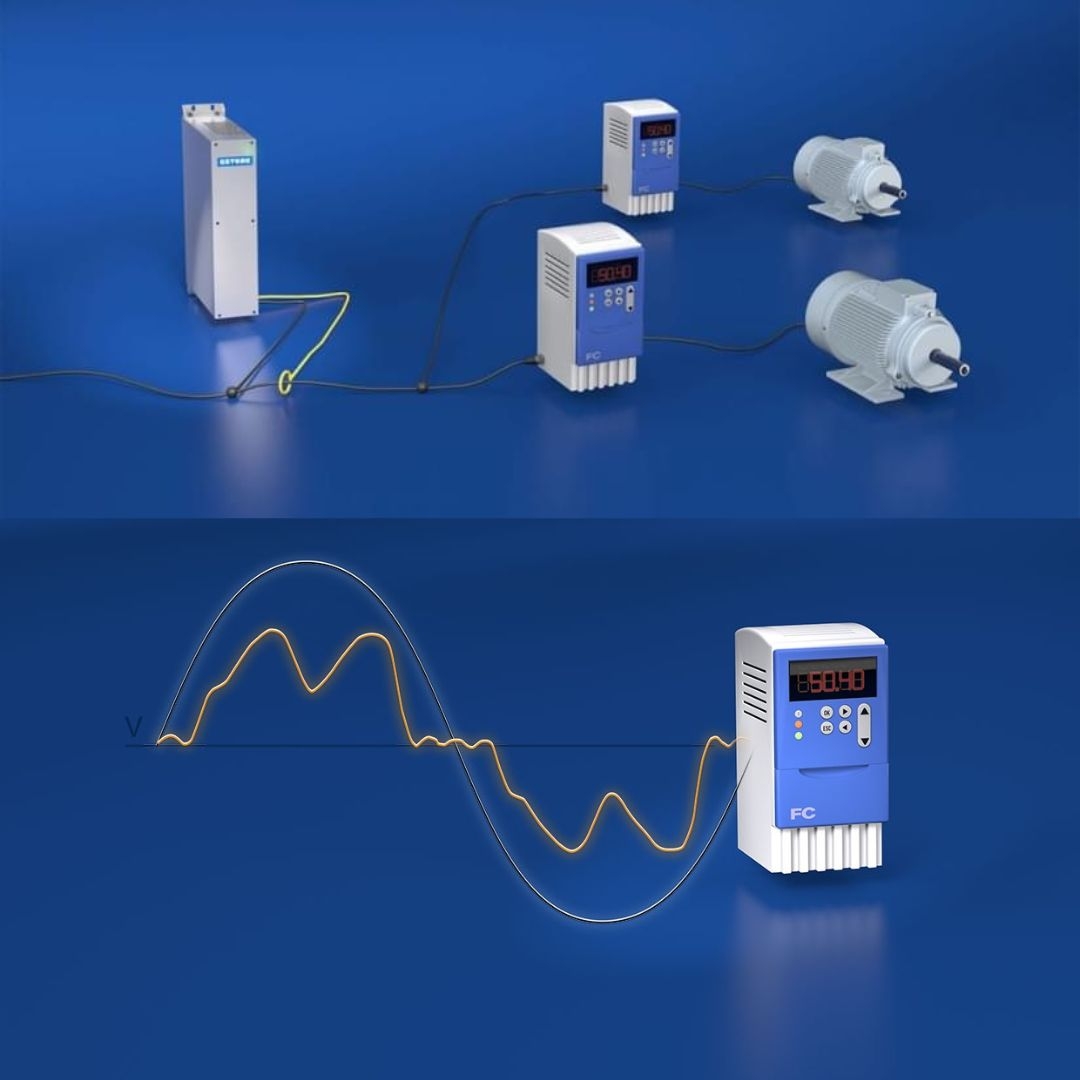

Harmonic Distortion

Harmonic distortion, also known as harmonics, is the prevalence of unwanted frequencies in electrical systems. It occurs only in non-linear loads. However, almost all industrial setups include significant non-linear loads. Consequently, it causes overheating of equipment and a drop in performance. Using quality harmonic filters, such as active harmonic filters, typically addresses this issue.

Flicker

Flicker is a more visual representation of voltage fluctuation in a power system. This occurs when there is a rapid change in load, causing the surrounding lights to flicker in their luminosity. This can adversely affect sensitive equipment and bring down the overall performance of the electrical system.

Poor Power Factor

Power factor is an important metric to measure the energy efficiency of an electrical system. It can be defined as the rate of efficiency at which equipment utilizes the input power without creating reactive power. It is measured from the range of 0 to 1, with 0 being the lowest and 1 being the highest power factor.

Poor power factor is a major concern for industrial setups as it not only reduces energy efficiency, but it can also lead to compliance issues, as there are ordinances in place to maintain a certain power factor.

Imbalance in Three-Phase Systems

Voltage imbalance, or imbalance, is another common issue, seen mostly in three-phase systems. This is unavoidable in some ways and requires careful monitoring, as even a small shift in voltage leads to major changes in current and operating temperature.

Root Causes of Power Quality Problems

What causes power quality issues in industrial systems? Here’s a look at some common causes:

Non-linear Loads from Industrial Equipment

Non-linear load is a condition where the current being drawn is not proportional to the voltage. Variable speed drives are one of the most common sources of non-linear loads. It leads to a lot of other complications, such as voltage distortion and overheating.

Aging Electrical Infrastructure

Aging electrical infrastructure can also impact power quality in an industrial setting. The main reason is that it impacts the overall performance, energy efficiency, longevity and reliability of the electrical system. This can, in turn, lead to a whole host of other problems such as harmonic distortion, voltage sags and surges, and power factor issues, requiring the use of proper power quality solutions such as an active harmonic filter to address them.

Environmental Factors

Environmental factors, particularly those caused in the renewable energy generation sector, can have an adverse impact on overall power quality. The two most common examples are solar power and wind energy generation. The main reasons causing power quality issues are changes in sunlight and wind speeds, which impact the overall output of the system.

This can also cause voltage fluctuations as well as introduce unwanted harmonics into the electrical system.

Grid-Level Instabilities

If the electrical grid is overburdened, it can cause some instability, impacting the smooth flow of current. This can lead to power disruptions and eventually cause power quality problems such as transients in the system. It also contributes to increased energy losses, making the system highly inefficient.

How Power Quality Issues Impact Industrial Operations

Power quality issues have a lot of negative side effects, such as:

Downtime and Equipment Failure

It can lead to the generation of harmonics, voltage fluctuations and more, which can directly or indirectly contribute to equipment failure. At the very least, it can lead to repair or reduction in the performance of sensitive equipment. Repairing it can lead to increased downtime and reduce the overall efficiency of the operation.

Increased Maintenance Costs

Since the equipment can face problems in the form of overheating or damage to insulation, it can cause frequent breakdowns. This means that the maintenance cost of running this equipment will increase exponentially as long as the power quality issues are not addressed.

Energy Inefficiency

Another prominent side effect of power quality issues is energy inefficiency. Since voltage fluctuations and harmonics bring down the overall power factor of the electrical system, it is also implied that it will draw more energy to perform its operation. This energy inefficiency will indirectly drive up the cost of power consumption.

Compliance and Safety Risks

Lastly, power quality issues also pose a risk in the form of non-compliance and potential safety risks for the operators. Many industries have strict standards regarding harmonics and the allowable range of power factors. If the underlying issues are not addressed with the help of proper power quality solutions, such as active harmonic filters, it can result in compliance failure and cost companies money in the form of penalties.

Moreover, since equipment can malfunction due to electrical surges, it poses a safety risk for operators as well.

Diagnosing Power Quality Issues: Tools and Techniques

Step-by-Step Diagnostic Process

- Conduct a Site Survey: Take stock of all different types of equipment and machines used in the industrial system.

- Install Power Quality Analyzers: Use different diagnostic tools to understand the power quality of the system, so there is verifiable data.

- Record and Analyze Events: When anomalous events occur, such as voltage sags, swells or flicker, keep a record of them.

- Compare Against Standards (IEEE 519, EN 50160): Compare the readings taken by the analyzers with the allowable standards such as IEEE 519 and EN 50160.

- Identify the Source (Internal vs. External): Lastly, identify if the source of the power quality issues is internal or external. This is vital to mitigate the challenges to a significant degree.

Checklist for Power Quality Monitoring

While it has already been stated that monitoring power quality is important, there is a certain protocol to do this monitoring effectively. Here’s a look at some fundamental steps:

- Identify critical equipment: Identify equipment in the industrial system that is either sensitive or a major contributor to non-linear loads, such as variable frequency drives.

- Monitor peak load times: Keep a note of times or instances when the load acting on the system is maximum. This is an excellent time to identify any power quality issues that are most likely to surface.

- Record voltage/current continuously: Keep note of the voltage and current to see how far off or disproportionate they are from each other.

- Flag any repetitive anomalies: If any anomalies, such as voltage fluctuations and harmonics, are persistent, flag them and keep a record.

- Generate monthly trend reports: Finally, with all the data provided above, generate a detailed monthly report so the system’s performance can be judged on a proper time frame.

Solutions to Power Quality Issues

Apart from detailed analysis and diagnostics, what are some viable solutions to address power quality issues? Here are a few common power quality solutions:

Passive and Active Harmonic Filters:

These are prominent power quality solutions that are mainly designed to tackle harmonics in the industrial system. Passive covers fixed harmonics, whereas an active harmonic filter is designed to handle dynamic loads and frequencies in real-time.

Power Factor Correction Capacitors:

This is another solution to tackle power factor issues in an electrical system by providing reactive current to offset the lagging current caused by inductive loads in the circuit.

Isolation Transformers and Surge Protectors:

These are two different types of equipment with distinct applications. While isolation transformers act as a barrier to trap power quality issues in a circuit and prevent them from affecting other connecting circuits, surge protectors save the system from sudden surges in voltage by absorbing them.

UPS and Voltage Regulators:

The primary function of both UPS and voltage regulators is the same. They are designed to protect various equipment from voltage fluctuations. However, where they operate varies. While UPS offers stability during power outages, voltage regulators provide stability in the input part of the circuit.

Real-Time Monitoring Systems:

This is a complex system that monitors and records data in real-time so that valuable data can be immediately processed and acted upon.

Integrating Active Harmonic Filters for Long-Term Stability

How They Work

Active harmonic filters operate by analyzing the input power and seeing if it has any harmonics. To counteract this incoming harmonic distortion, it sends a signal that is the same in magnitude but completely opposite in phase. This helps active harmonic filters to address any fluctuations in harmonics in real-time.

Benefits for Industrial Plants

Due to the real-time mitigation of active harmonic filters, it can almost automate the process of harmonic mitigation, ensuring excellent power quality effortlessly. All one has to do is install and invest in high-quality active harmonic filters.

Implementation Best Practices

When is it best suited to opt for active harmonic filters? They are the ideal choice when there is a significant non-linear load, a highly variable load, or a large degree of harmonic pollution, requiring prompt harmonic mitigation.

Future of Power Quality in Smart Industrial Setups

Role of AI and IoT in Predictive Power Quality Management

With artificial intelligence and Internet of Things (IoT) reshaping the industrial landscape, their input can also play a major role in improving power quality. The biggest benefit of integrating these technologies is that they can offer real-time data and also provide future trends based on past data. Therefore, they are excellent ways to perform predictive management of power quality.

Integration with Industry 4.0 Systems

Using AI and IoT with power quality systems such as active harmonic filters will become an integral part of Industry 4.0. With the integration of these power quality solutions with the advances in technology, there will be a marked increase in productivity and system performance.

FAQs

1. What causes poor power quality?

There can be numerous causes of poor power quality, such as harmonic distortion, voltage sags and surges, non-linear loads, transients, flicker and more.

2. How do harmonics affect industrial equipment?

Harmonics can damage industrial equipment by overheating, cause damage to insulation, and lead to a drop in their performance.

3. What is the ideal power factor for industrial facilities?

In theory, the ideal power factor should be 1, as it is rated between 0 to 1. However, since it is an ideal, in practice, a power factor of 0.9 is considered to be almost perfect.

4. Can poor power quality damage machines?

Yes, poor power quality can damage sensitive machines due to overheating or cause repairs at the very least, leading to increased downtime.

5. How do active harmonic filters improve power quality?

Active harmonic filters improve power quality by tackling harmonic distortion in real-time. So, whether it is dynamic or static in nature, active harmonic filters are designed to tackle any order of harmonics effectively.

We are currently working on bringing you the full version of our site. Some of the functionalities may be limited at this time.

If you have any questions about the services we offer don’t hesitate call us at +1 (877) 236-8337.